INTRO- MANUFACTURING

The term “Manufacturing” comes from two Latin words- ‘Manu’ means hand and ‘facture’ means to make.

It means producing goods in large quantities from raw materials and adding value to them through processing, machinery, and labour.

It is a secondary activity because it converts primary materials (from agriculture, mining, etc.) into finished products.

*Relation Between Agriculture and Industry

Agriculture and industry are interdependent:

- Industry provides inputs to agriculture – e.g., fertilizers, pesticides, irrigation pumps.

- Agriculture supplies raw materials like cotton, jute, sugarcane, and food grains for industries.

#Both sectors support each other’s growth and sustainability.

IMPORTANCE OF MANUFACTURING

Manufacturing plays a vital role in the economic and social development of a nation.

- Increases National Income:

- Adds value to raw materials and contributes to the Gross Domestic Product (GDP).

- Generates Employment:

- Provides direct and indirect job opportunities to millions.

- Modernises Agriculture:

- Agro-based industries support farmers by providing tools, machinery, fertilizers, and transport facilities.

- Promotes Export and Foreign Exchange:

- Industrial products like textiles, machinery, and chemicals earn foreign exchange.

- Reduces Regional Imbalances:

- Industrial development helps spread economic growth evenly across regions.

- Strengthens the Economy:

- Makes the nation more self-reliant and reduces dependence on imported goods.

CONTRIBUTION OF MANUFACTURING TO NATIONAL ECONOMY

- Manufacturing sector forms the backbone of India’s economy.

- It helps in transforming a country from agrarian (farming-based) to an industrial economy.

- The National Manufacturing Policy (NMP) aims to increase manufacturing’s share in GDP and create more employment opportunities.

INDUSTRIAL LOCATION

Industrial location refers to the specific place or area where an industry is set up. Industries tend to locate where all necessary inputs are easily and cheaply available.

According to Alfred Weber’s Industrial Location Theory,

“An industry is located at a place where the cost of production and transportation is minimum.”

*Factors Affecting the Location of Industries

Industries do not grow everywhere — they develop where conditions are favourable.

The major factors are given below.

1. Availability of Raw Materials

- Industries are mostly established near sources of raw materials to reduce transportation cost.

2. Labour (Manpower)

- Skilled and unskilled labour is essential for production.

- Industries are located in areas with abundant, cheap, and efficient labour.

3. Power (Energy Source)

- Industries need continuous power supply for running machines.

- Areas near coal, hydroelectric, or thermal power plants attract industries.

4. Capital (Investment)

- Establishing and running industries requires huge capital (money).

- Therefore, industries prefer areas with availability of banking and financial institutions.

5. Market

- A large and nearby market ensures quick sale of products.

- Industries are set up where there is high demand and easy transport to consumers.

6. Transport and Communication

- Efficient road, rail, port, and communication facilities help industries get raw materials and send finished goods to markets.

7. Government Policies

- Government provides tax benefits, subsidies, and special industrial zones to promote industrial growth.

8. Industrial Climate (Social and Political Stability)

- Industries develop better in areas with peace, good governance, skilled workforce, and supportive environment.

*Industrial Clusters or Agglomeration

-When several industries are set up close to each other for mutual benefit, it is called industrial agglomeration.

-These areas become industrial hubs or regions.

-Example:

- Mumbai–Pune industrial region

- Ahmedabad–Vadodara region

- Chotanagpur plateau (iron and steel industries)

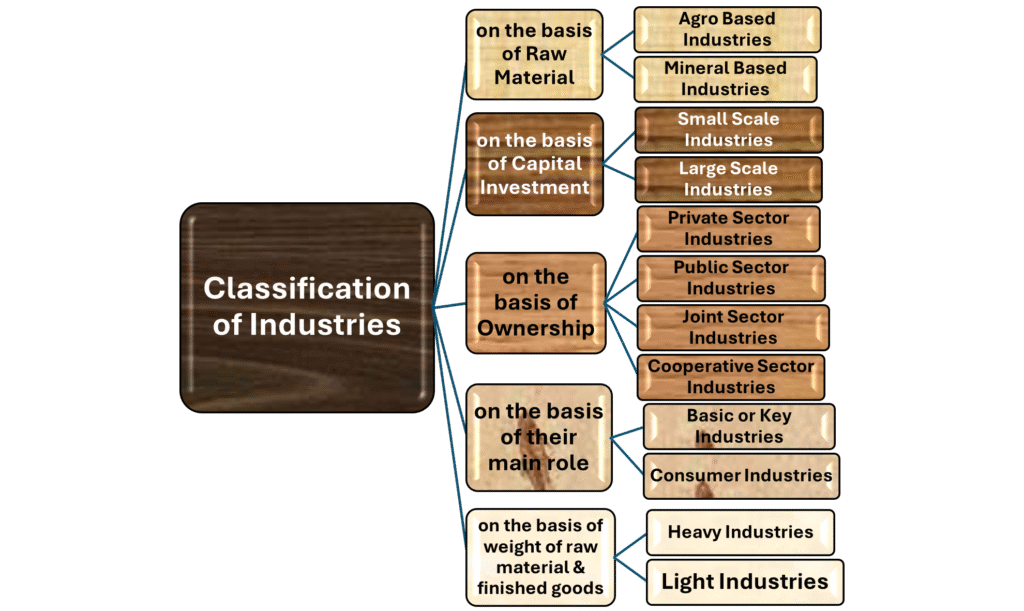

CLASSIFICATION OF INDUSTRIES

Industries can be classified or grouped on different bases such as raw materials, capital investment, ownership, and size.

This helps in understanding their nature, functioning, and contribution to the economy.

AGRO-BASED INDUSTRIES

Agro-based industries are industries that use agricultural products as raw materials.

They form a strong link between agriculture and industry, and are the largest group of industries in India.

These industries process agricultural raw materials into finished or semi-finished goods that can be used by consumers or other industries.

1. Textile Industry

- The textile industry is the oldest and largest industry in India.

- It is an agro-based industry as it uses raw materials from agriculture like cotton, jute, silk, and wool.

- It is also a labour-intensive and export-oriented industry.

- Contributes 4% to India’s GDP and about 20% to industrial production.

- The first successful textile mill was established in Mumbai in 1854.

2. Cotton Textile Industry

- The cotton textile industry is the oldest and most important industry in India.

- Largest organized sector in Indian manufacturing.

- India is one of the largest producers of cotton in the world.

- India exports yarn to Japan.

- The country also export cotton goods to U.S.A., U.K., Russia, France, East European countries, Nepal, Singapore, Sri Lanka, and African countries.

3. Jute Industry

- The jute industry is one of the oldest agro-based industries in India.

- It uses jute fibre, known as the “golden fibre”, as its main raw material.

- Jute is used to make gunny bags, ropes, mats, carpets, and other packaging materials.

- India is the largest producer of raw jute and the second-largest exporter of jute goods (after Bangladesh).

- It grows well in hot and humid climate with plenty of rainfall.

- Main jute-producing states: West Bengal, Bihar, Assam, Odisha, and Meghalaya.

- The delta region of the Ganga and Brahmaputra rivers

- Problems Faced by the Jute Industry

- Competition from synthetic substitutes

- Competition from Bangladesh, which has cheaper labour and better quality jute.

- Old machinery

- Irregular supply of raw jute due to monsoon dependence.

- Labour unrest

4. Sugar Industry

- India is the second-largest producer of sugar in the world (after Brazil).

- This industry plays a key role in the rural economy by providing employment and supporting farmers.

- Sugarcane is a tropical and subtropical crop grown in almost all parts of India.

- Main sugarcane-producing states: Uttar Pradesh, Maharashtra, Karnataka, Tamil Nadu, Bihar, Punjab, and Haryana.

MINERAL BASED INDUSTRIES

1. Iron and Steel Industry

- The Iron and Steel Industry is known as the “backbone of modern industry”.

- It provides basic raw material for many industries such as engineering, construction, shipbuilding, automobiles, and machine tools.

- It is a heavy industry because raw materials and finished products are bulky and heavy.

- This industry is crucial for industrial growth and economic development of the country.

- India ranked 4th among the world unrefined steel producers and largest producer of sponge iron.

- China is the largest producer of steel and also the world’s largest consumer of steel.

- In 2004, India was the largest exporter of steel

- Chotanagpur plateau region has the maximum concentration of iron and steel industries.

2. Aluminium Smelting

- Aluminium smelting is the process of extracting pure aluminium metal from its ore, bauxite.

- It is one of the most important metallurgical industries in India.

- Aluminium is called a “metal of the future” because of its light weight, strength, corrosion resistance, and conductivity.

- It is light, resistant to corrosion, a good conductor of heat, mallable and becomes strong when it is mixed with other metals.

- Used to manufacture aircraft, utensils and wires.

- It has gained popularity as a substitute for steel, copper, zinc and lead in a number of industries.

- are located in Odisha, West Bengal, Kerala, Uttar Pradesh, Chhattisgarh, Maharashtra and Tamil Nadu.

3. Chemical Industries

- The Chemical Industry is one of the oldest and fastest-growing industries in India.

- It provides basic raw materials to several industries such as paper, textiles, paints, plastics, fertilizers, and pharmaceuticals.

- It contributes approximately 3 percent of the GDP.

- It is the third largest industry in Asia and twelfth largest in the world in term of its size.

- Organic and inorganic sectors of Chemical industry are rapidly growing.

4. Fertiliser Industry

- It plays a vital role in increasing agricultural productivity and supporting the Green Revolution.

- Fertilisers provide essential nutrients like nitrogen, phosphorus, and potassium to the soil, improving crop yield and soil fertility.

- India is the third-largest producer of nitrogenous fertilisers in the world.

- Main states having this industry are: Gujarat, Tamil Nadu, U.P., Punjab and Kerala.

5. Cement Industry

- It plays a key role in infrastructure development — building houses, roads, dams, bridges, and factories.

- Cement is called a “basic building material” and is essential for the construction sector.

- India is the second-largest producer of cement in the world, after China.

- The first cement plant was set up in Chennai in 1904.

- The industry has strategically located plants in Gujarat.

- This industry requires bulky and heavy raw materials like limestone, silica, alumina and gypsum.

6. Automobile Industry

- The Automobile Industry is one of the fastest-growing industries in India.

- It manufactures vehicles for road and rail transport, including cars, trucks, buses, motorcycles, scooters, and commercial vehicles.

- The automobile sector is known as a “sunrise industry” because of its rapid expansion and technological advancement.

- It is a key driver of industrial growth, contributing significantly to India’s GDP, employment, and exports.

7. Information Technology and Electronics Industry

- This industry produces a wide range of electronic products and provides software and IT-enabled services (ITeS).

- It has revolutionized the Indian economy and established India as a global IT hub.

- Bangalore is considered as the electronic capital of India.

- The major IT industry concentration is at Bangalore, Noida, Mumbai, Chennai, Hyderabad and Pune.

INDUSTRIAL POLLUTION AND ENVIRONMENTAL DEGRADATION

Industrial pollution refers to the contamination of the environment due to harmful by-products released from industries into air, water, and soil.

Industries are responsible for four types of pollution: Air, Water, Land, Noise

*Measures to Control Industrial Pollution

To reduce pollution and promote sustainable development, the following steps are essential:

- Treat waste before discharge

- All industries should treat liquid and solid wastes in Effluent Treatment Plants (ETPs) before releasing them into water bodies.

- Reuse and recycle waste materials

- Reusing materials like paper, plastic, and metal reduces pollution and saves resources.

- Adopt cleaner and eco-friendly technologies

- Industries should use biogas, solar, and wind energy instead of fossil fuels.

- Proper waste disposal

- Industrial solid waste should be scientifically managed rather than dumped openly.

- Plant trees and maintain green belts

- Green belts around industrial areas act as pollution barriers.

- Government laws and awareness

- Implementation of environmental laws like the Environment Protection Act (1986) and pollution control boards should be strengthened.